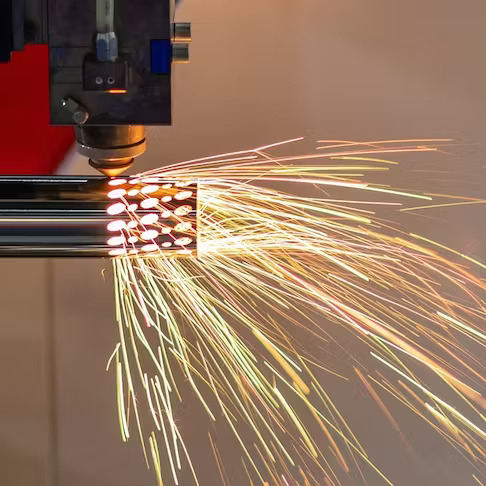

Sheet Metal and Heavy Metal Fabricating involves specialized skills applied to sheets and plates stock to form, fabricate, or manufacture according to requirements expressed in blueprints, specifications, and technical orders. Services include cutting, bending, punching, stamping, welding and finishing. These techniques complement each other and play vital role in the successful completion of a project.

Big or small, Thick or Delicate, If it’s Metal, We can cut it, Fabricate it, Finish it & Ship it.

Beyond Limits : From 2 Tons to 20 Tons

In a world of ever-evolving technologies, we thrive on pushing boundaries. A single job encompasses a vast range – from the finesse of 2-ton sheet metal works to the monumental scale of 20-ton heavy metal fabrications. Our versatility is matched only by our determination to execute each project flawlessly.

Crafting Dreams : If It's Metal, We Master It

Whether the task at hand is immense or delicate, whether the metal is thick or slender, our expertise remains unwavering. From inception to execution, we handle each facet – cutting, fabricating, finishing – with a blend of artistry and precision. If it's metal, we embrace the challenge, shaping it into remarkable creations that transcend expectation.

In every piece we craft, we blend technical prowess with artistic vision, culminating in metalwork that stands as a testament to our commitment to quality, innovation, and boundless creativity. With every project, we etch our legacy in metal, breathing life into the ordinary and shaping the extraordinary.